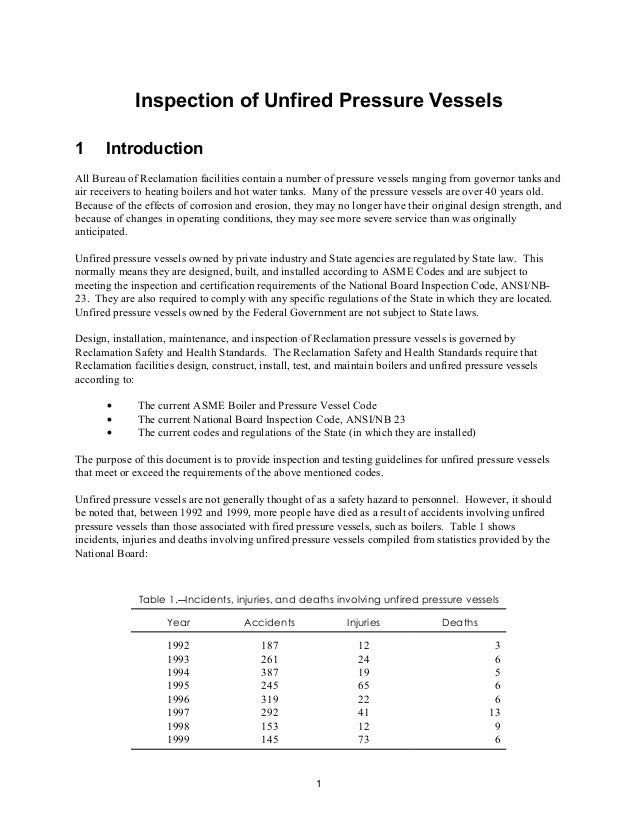

Pressure vessel definition based on the asme code section viii pressure vessels are containers for the containment of pressure either internal or external.

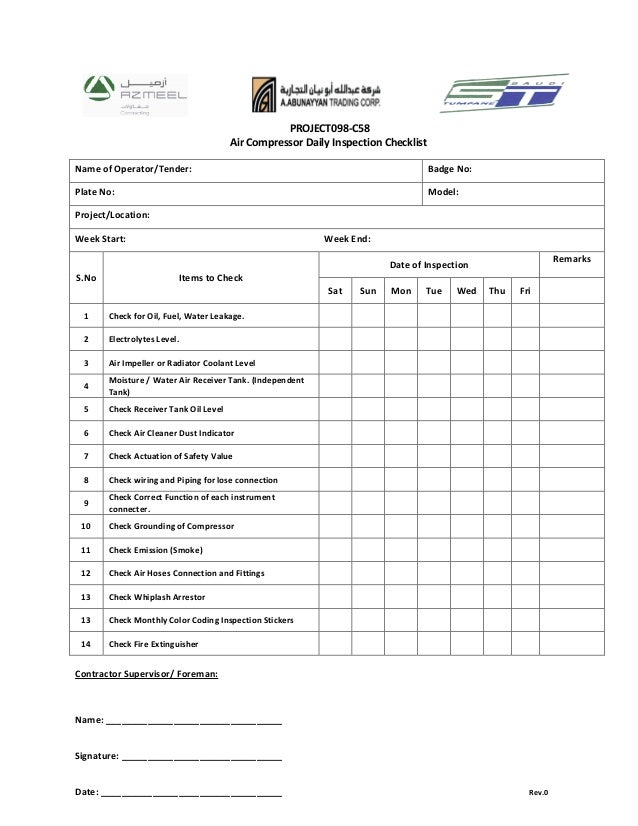

Air receiver tank inspection checklist.

This checklist covers regulations issued by the u s.

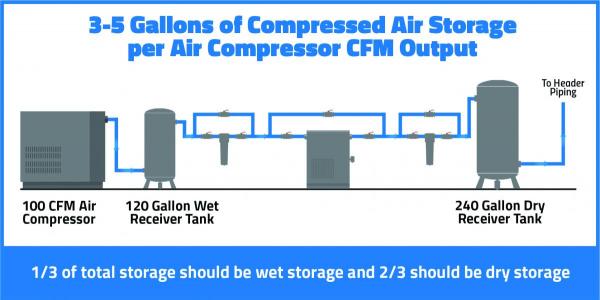

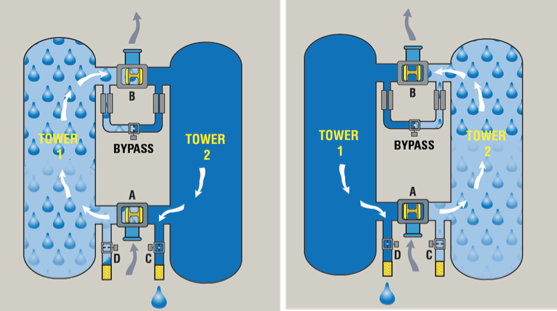

There should be a suitable appliance either manual or automatic for draining the receiver.

Every 2 years.

Maintenance service inspection of air receivers compressors the receiver should be fitted with a correct pressure gauge complying with bs 1780 or similar equivalent standard and which indicates pressure in bar lbf sqin or other suitable units.

The common dictionary definition for an air receiver is a storage vessel for compressed air usage ame can assume therefore that only pressure vessels less than 150 litres which fall under the definition of a storage vessel for compressed air or gas usage should be part of this exception to statutory inspections.

This pressure may be obtained from an external source or by the application of heat from a direct or indirect source or any combination thereof.

Visual inspection and running tests.

Visual examination on the surface of the external shell.

It applies to air compressor tanks compressed air receivers used to store compressed air generated by an air compressor and other equipment used in providing and using compressed air for operations such as cleaning drilling hoisting and chipping.

Visual inspection and running tests.

If the responsible person needs an external inspector then one option is to.

Boiler and pressure vessel code section viii which is incorporated by reference as specified in sec.

A competent person as appointed by the responsible person owner user of the air receiver shall undertake the statutory e g.

Department of labor osha under general industry standard 29 cfr 1910 169.

This checklist covers regulations issued by the u s.

However due to minimum size inspection thresholds employed by the vast majority of jurisdictions many of the smaller air receivers will not qualify for a mandatory inservice inspection.

Observed that the receiver is cutting out at the correct maximum presurre.

Description and overview an air receiver is probably the most common type of unfired pressure vessel.

Visual inspection and running tests.

Department of labor osha under general industry standard 29 cfr 1910 169.

Air compressor inspection checklist pmt no signature is there any external signs of damage to the receiver or component parts.

All new air receivers installed after the effective date of these regulations shall be constructed in accordance with the 1968 edition of the a s m e.

2 and 4 yearly inspections.

Are compressor provided with a drain valve and removal of accumulated oil and water.