Even if you are not considering construction of an aluminum airplane the odds of using several sheet metal skills in building your aircraft are high.

Aircraft sheet metal assemblers.

1 2 years of sheet metal assembly aircraft sheet metal structure experience or a completed airframe and powerplant a p license.

Fit and fasten sheet metal coverings to surface areas or other sections of aircraft prior to welding or riveting.

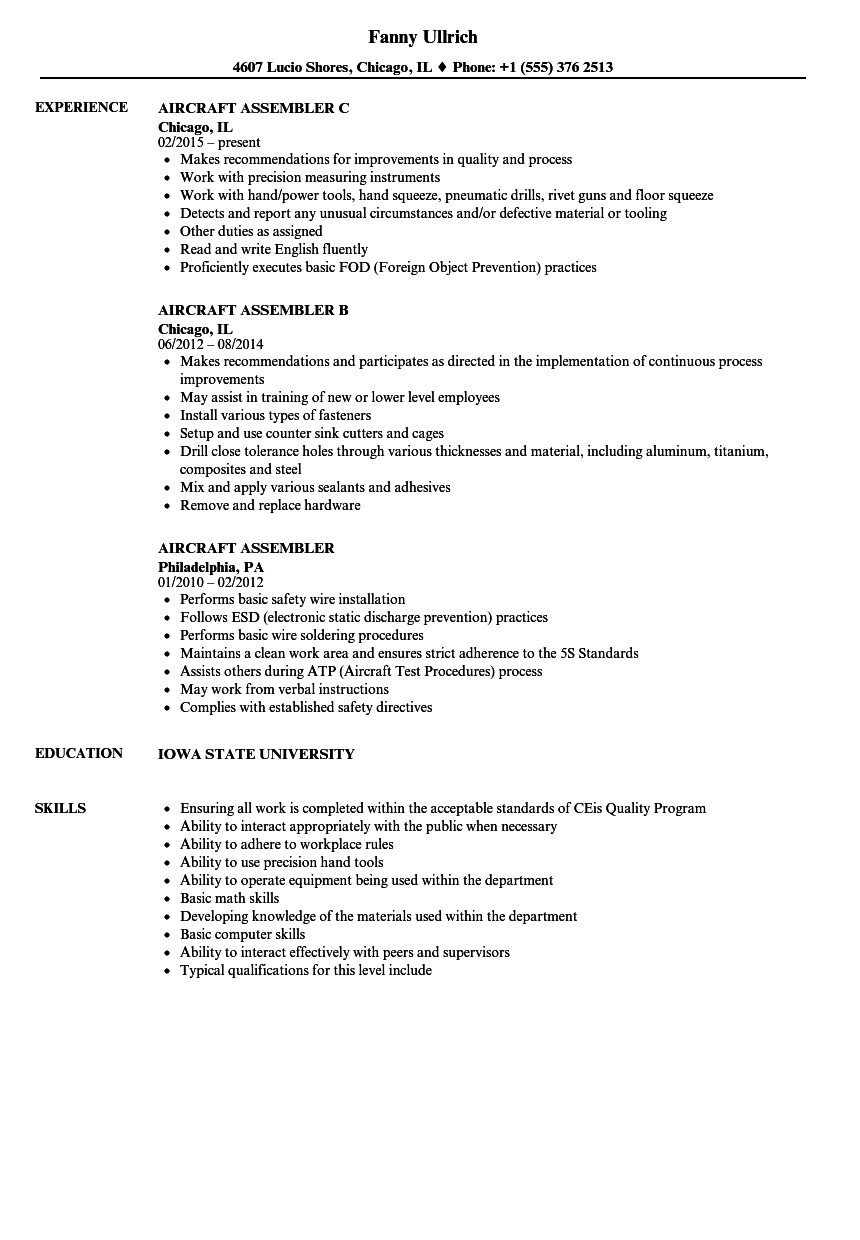

Aircraft assembler resume examples.

Aircraft assembler employers may require applicants to have experience with welding reading blueprints and working with sheet metal.

Description performs a variety of operations to manufacture assemble and or refurbish various aircraft parts and structures basic qualifications.

Many small colleges and technical schools offer certificate.

Individual job duties may include.

Typical duties listed on a resume sample for aircraft sheet metal mechanic include reading blueprints trimming parts maintaining system components inspecting and testing units verifying tension of cables and capturing waste materials.

Inspector assembly sub assembly precision mechanic aircraft production mechanic electrical and radio sheet metal assembler and riveter.

Apply to installer mechanical assembler sheet metal mechanic and more.

Typical job duties listed on an aircraft assembler resume sample are reading blueprints measuring and welding parts working with sheet metal using power tools and updating their education continuously.

Sheet metal construction is used on a large majority of aircraft in one form or another.

Aircraft sheet metal mechanics fit and assemble parts of airplanes and space vehicles.

Aircraft assemblers put together parts to obtain different kinds of aircraft.

Often tube and fabric airplanes will have aluminum cowlings fairings etc.

Assembly mechanic encompasses all of the duties of the following job classifications.

Capture or segregate waste material such as aluminum swarf machine cutting fluid or solvents for recycling or environmentally responsible disposal.