As mentioned above the unified numbering system for metals and alloys uns was developed by astm and sae in an effort to clear up the alphabet soup problem.

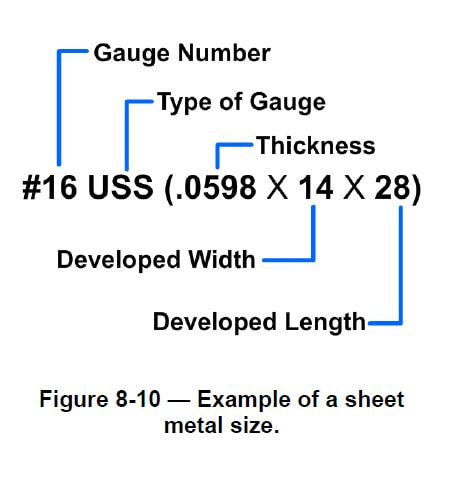

Aircraft sheet metal numbering system.

Various numbering systems are used to facilitate the location of specific wing frames fuselage bulkheads or any other structural members on an aircraft.

Many manufacturers consider the center line of the aircraft to be a zero station.

Once drilled use a pin punch to tip off the rivet head and drive the remaining shank out of the hole while supporting the surrounding metal.

The lower number in the cell is the bend allowance per 1 of bend.

To locate structures to the right or left of the center line of an aircraft a similar method is employed.

Types of shrinking and stretching tools used for aircraft metal structural repair.

Forming at room temperature is known as cold forming.

The tools required for this type aircraft are minimal.

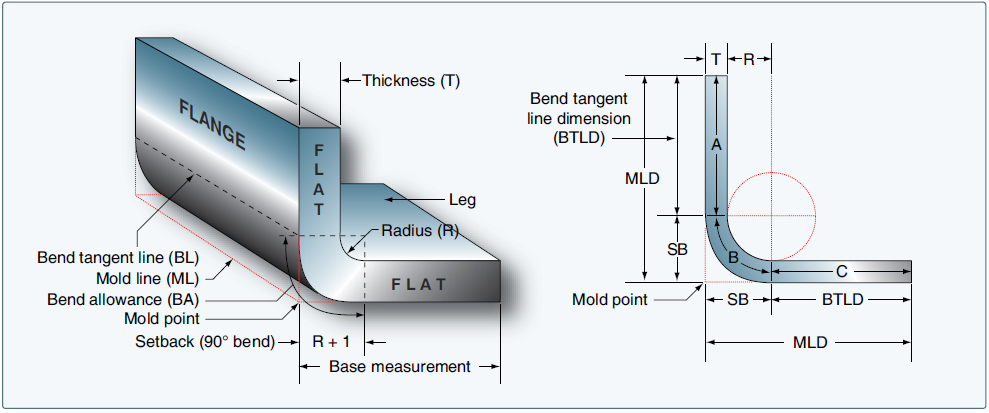

Base measurement is the outside dimensions of a formed part.

Natural grain of the material is formed as the sheet is rolled from molten ingot.

Department of transportation federal aviation administration 800 independence avenue sw washington dc 20591 866 tell faa 866 835 5322.

In figure 5 the radius of bend is shown on the top line and the metal thickness is shown on the left hand column.

How bend calculations are used in a bending operation.

Aircraft technician relies on a wide variety of powered and hand operated tools to precisely bend and fold sheet metal to achieve the perfect shape.

The third digit the sheet type is a number that represents the type of drawings that are on the sheet plans sections details schedules etc.

Center punch the rivet then drill just to the base of the rivet head with the same size or one size smaller drill.

The terms are used in sheet metal forming and flat pattern layout.

The upper number in each cell is the bend allowance for a 90 bend.

Bend allowance and bend radius all the space between the band tangent lines is the.

Manufacturers use some system of station marking.

The final two digits the sequence numbers are numbers that simply place the sheets in order.

Some sheet metal aircraft utilize construction techniques that use nothing but pop rivets that are pulled using a small inexpensive rivet tool.

To determine the bend allowance for a 90 bend simply use the top number in the chart.

Aircraft hardware is discussed in detail in the structural hardware manual navair 01 1a 8.

Forming sheet metal requires a variety of tools and equipment both powered and manual.

Flange is the shorter part of a formed angle.

Aircraft hardware is usually identified by its specification number or trade name.

Any bend formed on a.